Laser welding application for the connector cover

Hello, could you assess whether this cover can be made using deep drawing? A client’s message popped into our mailbox with a 3D drawing enclosed,

20 years experience in hardware development and manufacturing, mechanical, electrical and testing design.

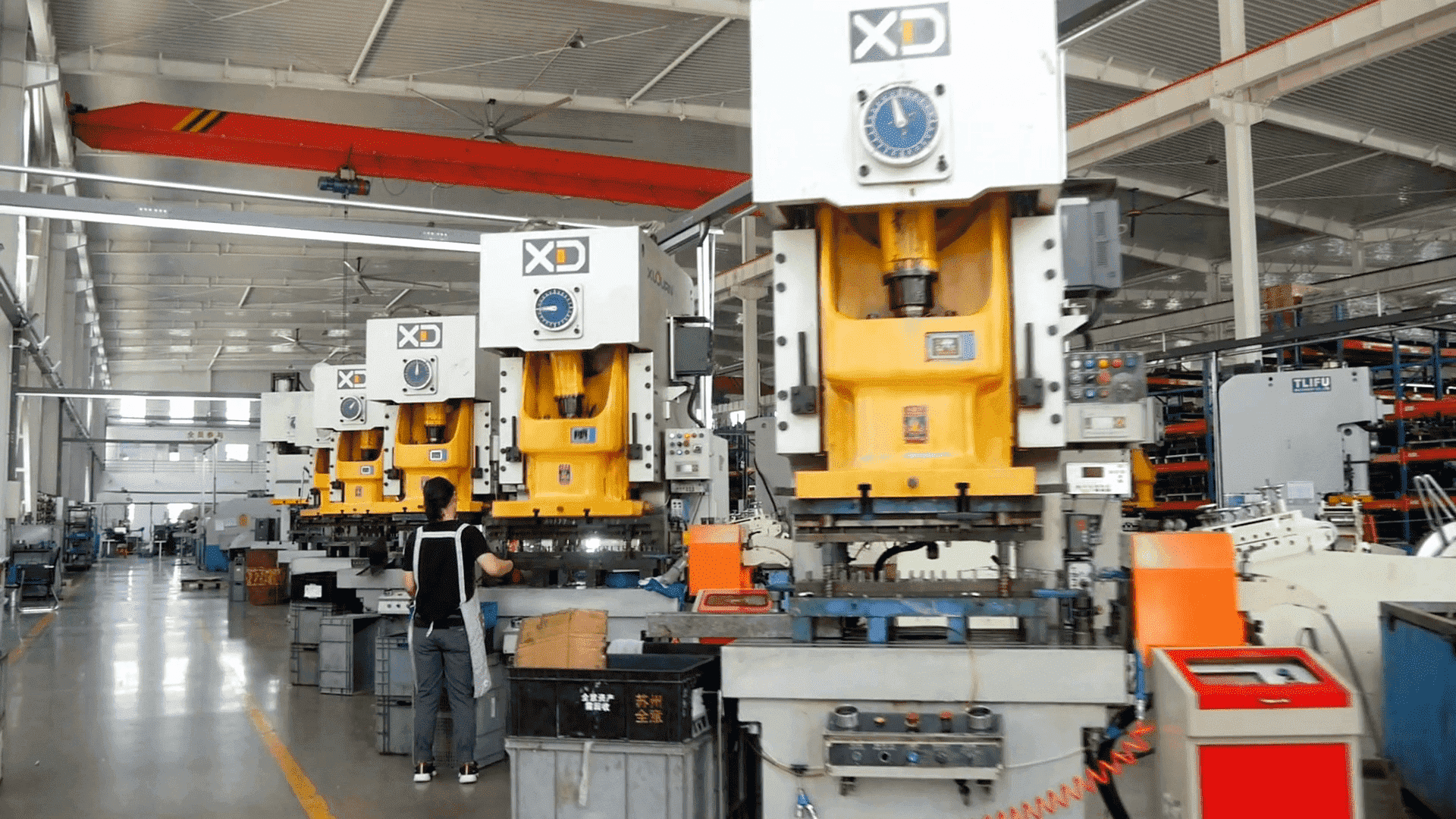

50 sets Pressing machines, 10 sets machining machines and 5 sets laser machine for 100,000pcs output per week.

Flexible production model single step and progressive pressing to meet your varied demanding in prototype and mass production.

Capability of 0.1~8mm metal sheet pressing, deep drawing, forming, casting and machining.

Inhouse mold development capability for a rapid response during development.

Expert engineer specializing in metal stamping: Skilled in complex part development, quality troubleshooting and cost-efficient production process implementation

Skilled at tailoring material adaptation to both application needs (e.g., durability, precision) and stamping process requirements (formability, machinability)

We ensure product quality via diverse testing/measurement equipment, verifying dimensional accuracy and mechanical performance rigorously.

We collaborate closely with customers throughout the entire project lifecycle, proactively addressing and resolving any challenging issues to ensure smooth progress and satisfaction.

Hello, could you assess whether this cover can be made using deep drawing? A client’s message popped into our mailbox with a 3D drawing enclosed,

Hello, we are glad to inform you that we accept your recommendation regarding welding a gold plated metal plate onto the alumina frame. Also, thanks

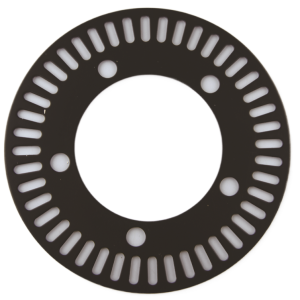

Hello, this is a small metal part that isn’t overly complex to produce, but it has high safety requirements. The order volume isn’t large, just